Warehousing and Logistics

Power Quality Solutions for Warehousing & Logistics

Today’s socio-economic climate has drastically changed consumer behavior, and with it, the retail landscape. E-commerce transactions are skyrocketing, from 14% of all retail transactions in 2019, to over 20% by 2023. This growth puts an imperative on warehousing and logistics operations to improve service levels, uptime, and profits.

Variable frequency drives (VFDs) play an integral role in the speed, efficiency, and overall performance of today’s distribution, warehousing, and logistics centers. Often found in conveyor systems, gearboxes, and sorting systems, VFDs unfortunately cause electrical harmonic distortion, which can damage electric motors over time and threaten production throughout the facilities. Expanded usage of rechargeable systems, such as battery-powered forklifts and warehouse robots, can also lead to an increase in polluted power and stray electrical signals.

Simply put, downtime is not an option within these facilities as regional distribution, warehousing, and logistics centers often process over 30,000 pieces per hour, for 20 contiguous hours. MTE’s industry-leading power quality solutions are built to help operations avoid profit-killing downtime by filtering the harmonic distortion caused by VFDs, which can lead to breakdown.

Modern warehouse and logistics centers have increased complexity and harmonic issues

- The motor control cabinet inside a facility provides integrated, precision control, but it’s also the leading cause of unwanted harmonics.

- Stray voltages can cause strain, overheating, and damage to gear box motors.

- Conveyor belt motors are often located 1,000 ft. or more from the drive unit, leading to heavy distortion from harmonics.

- Electrical “pollution” can damage the sorters and lifters found on conveyance systems.

- The increased use of battery powered forklifts and robotics require additional charging stations which ultimately drive up your facility’s harmonics.

Power Quality Challenges for Warehousing and Logistics

Warehouse facilities face a variety of power quality challenges, from both the line side and load side of the VFD. On the line side, unwanted harmonic loads throughout the system can lead to costly utility violations or nuisance tripping, while the harmonics generated on the load side often lead to premature motor and cable failure or motor bearing damage.

In addition, more facilities are using autonomous robots as part of their daily operations. While effective, the charging stations needed to recharge the robots throughout the day, can also create their own harmonics, which can adversely affect transformers.

Any and all of these challenges can lead to unexpected replacement expenditures and costly production downtime within your facility.

Unplanned Downtime

Motor and gearbox failures can result in numerous hours of maintenance, idled workers, and potential safety concerns.

Utility Compliance

IEEE-519 compliance is critical for industries to remain in accordance with local regulations.

Maintenance Staffing

Availability of specialized personnel during peak hours can be challenging, further extending downtime costs.

Damaged Shipments

Sudden stops or failures in sorting or conveyance can cause damage to valuable shipments, resulting in additional recuperation costs.

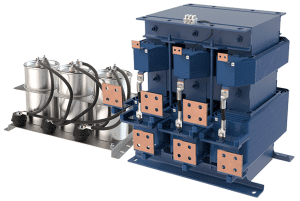

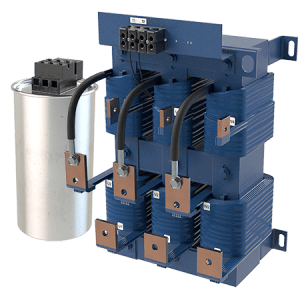

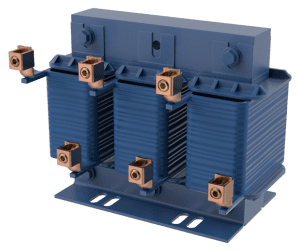

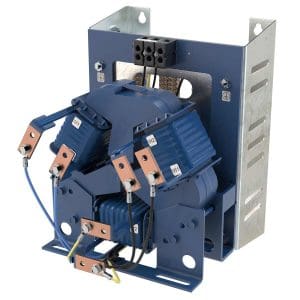

MTE Featured Warehousing & Logistics Solutions

MTE offers a complete line of power quality solutions for the warehousing and logistics industry that are aimed at lowering current distortions and protecting expensive equipment from damaging transient voltages. MTE solutions keep motors and cables running longer which ultimately results in energy savings at your facility.