Food and Beverage

Power Quality Solutions for Food & Beverage

Download Food & Bev Industry Brochure

High quality, safe production, and speed are paramount in the food and beverage industry. Strict regulations govern the manufacture of these products to ensure consumer safety. Consumer demand is also at an all-time high. These factors require manufacturers to rely on variable frequency drives (VFDs) to control the speed of conveyor belts, compressors, mixers, pumps, and other critical components within the process.

While highly efficient, VFDs produce damaging harmonics on the line and load sides of the drive, resulting in nuisance tripping, inaccurate system measurements, electric motor failure, and more. Production and food quality then suffer, creating substantial risk of spoilage and monetary loss.

As food and beverage consumers drive record online sales, estimated 15% – 20% by 2025, manufacturers will need to produce and deliver products faster. To address this demand, facilities will use more VFDs, thus creating greater necessity for harmonic mitigation.

MTE’s industry-leading power quality solutions filter out harmful harmonics generated by VFDs, and increase profitability for manufacturers by reducing motor breakdowns, avoiding downtime, preventing spoilage and waste, improving delivery times to the marketplace, and remaining compliant with utilities.

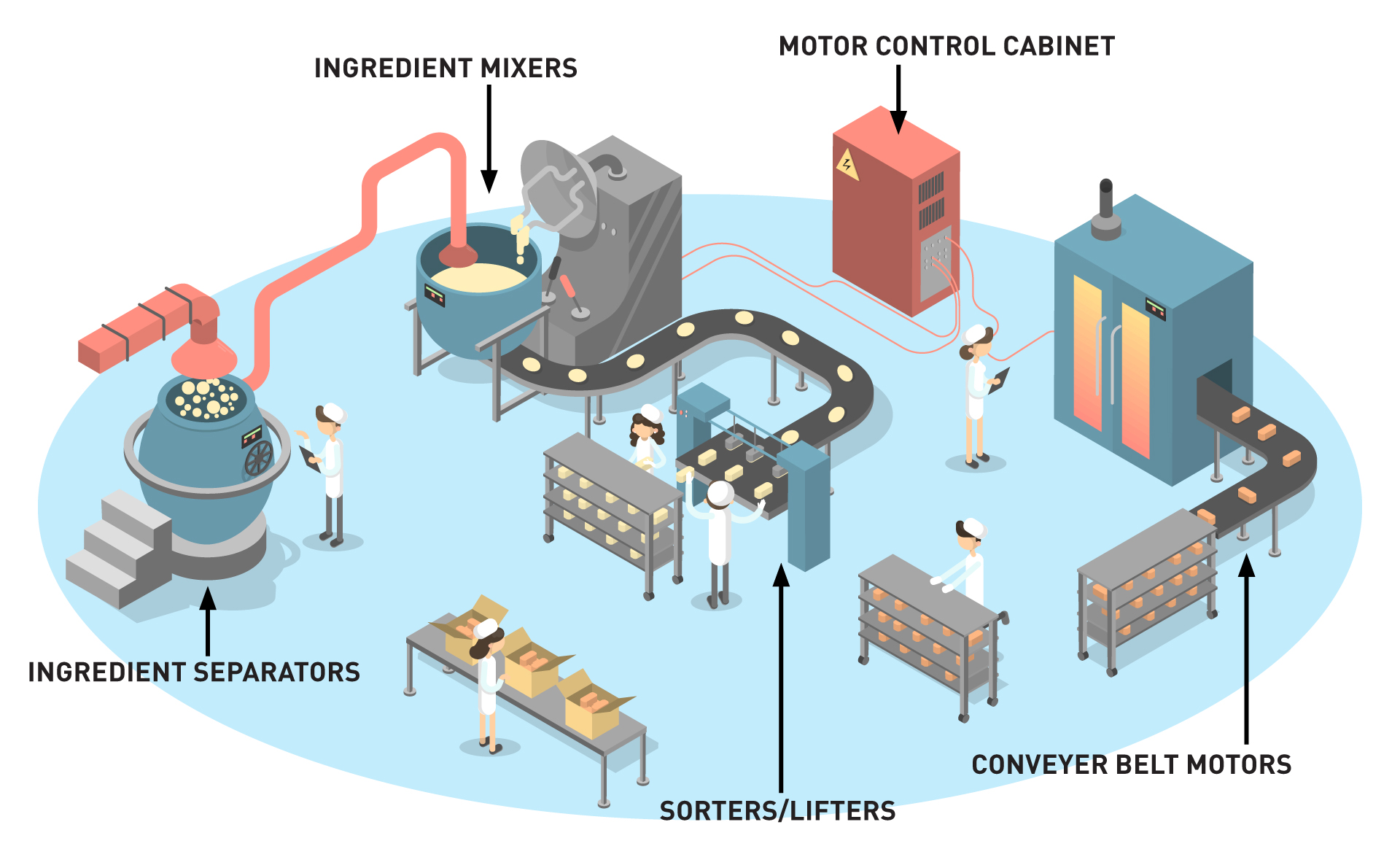

MODERN FOOD AND BEVERAGE FACILITIES HAVE INCREASED POWER COMPLEXITY AND HARMONIC ISSUES.

Ingredient Mixers

- Most common equipment used in food production

- VFDs control speed and torque to maintain superior food quality

Ingredient Separators

- Separates ingredients for proper food production and precise flavors

- VFDs control the required speeds and torque for food processing

Sorters/Lifters

- Work with conveyor systems to move food products between processes.

- VFDs control motors for transport speed

Conveyor Belt Motors

- Move food between processes

- VFDs control motors to vary transport speeds

Motor Control Cabinet

- Central location for VFDs that control motors and MTE products that mitigate harmonics.

POWER QUALITY CHALLENGES FOR FOOD & BEVERAGE FACILITIES

A common line side power quality challenge is that VFD generated harmonic distortion causes poor system performance, resulting in lower quality food and beverage products. If left unmitigated, these harmonics can also violate utility regulations and possibly result in fines.

Load side challenges are that VFDs are often hundreds of feet from the motors that drive conveyors. These distances can cause harmful harmonics to run through the cables, resulting in motor failures, unplanned downtime, and significant production losses.

Unplanned Downtime

With demand at all time highs, critical component failures may result in hours of maintenance, idled workers, and potential food safety concerns.

Food Quality and Safety

Precision control is required to ensure accurate measurements of ingredients; any blips in the process can lead to poor food quality and potentially unsafe consumption.

Automation Issues

Complex automation relies on VFDs to provide precise control of production equipment, but the harmful byproduct is harmonics which can damage motors.

E-Commerce Growth

Increasing food demand is placing more focus on ownership costs, and additional burden on equipment uptime and expected overall lifetimes.

Utility Compliance

IEEE-519 compliance is critical for industries to remain in accordance with local regulations.

Maintenance Staffing

Availability of specialized personnel during peak hours can be challenging, further extending downtime costs.

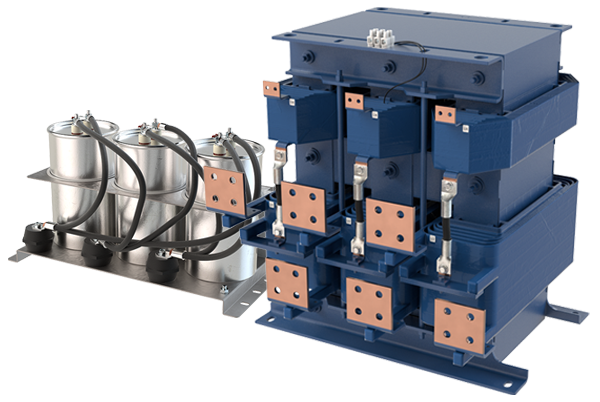

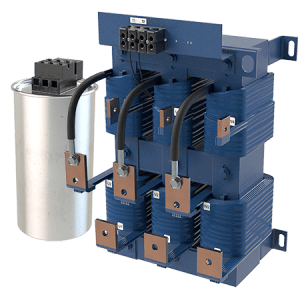

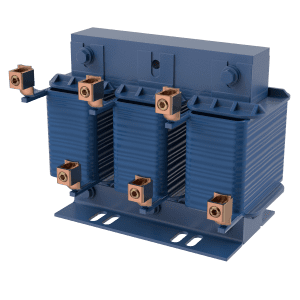

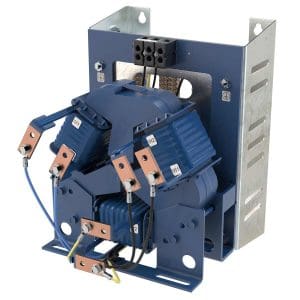

MTE Featured Food & Beverage Solutions

MTE offers a complete line of power quality solutions for the warehousing and logistics industry that are aimed at lowering current distortions and protecting expensive equipment from damaging transient voltages. MTE solutions keep motors and cables running longer which ultimately results in energy savings at your facility.

Line Side Solutions

Load Side Solutions